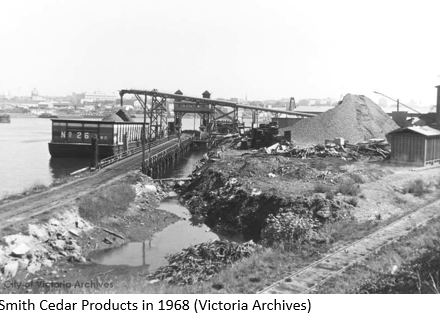

BC Forest Discovery Centre received two stencils from Gail Klein, whose husband worked in the shingle mill industry in the last month. Both stencils show grades of lumber and the name “Smith Cedar Products Ltd.,” a company established in 1955 near Point Ellice of Victoria by Hershell A. Smith (1920-1998). He bought out Horton Cedar Manufacturing Co. to build the shingle mill, and he owned the Oak Bay Lumber in Victoria and Sooke Forest Products.

In 1960, the Smith’s shingle mill had 8 shingle machines, employing 30 workers. The company kept growing, and by 1962 it had 13 shingle machines, three resaws, four grooving machines, and staining equipment, becoming one of the largest shingle manufacturers in BC. The company also experienced several problems, including two fires in 1959 and 1972, and an incident where an experienced staff member lost two of his fingers in 1975.

Moreover, there was a labor strike in 1968. 115 men joined the campaign to increase their wage by 50 cents per hour from the basic pay for shingle weavers of $2.76 per hour. Due to the frustrated American shingle market during the time, the Smith’s plant reduced its production to less than 50% capacity.

The lumber grades are carved into these stencils. One shows “No. 1 – 16” XXXXX” and the other says “No. 1 – 18” PERFECTIONS.”

16” XXXXX (also known as “FiveX”), 18” Perfections, and 24” Royal are standardized sizes of cedar shingles used in North America, published by the Cedar Shake & Shingle Bureau (CSSB) based on the Uniformed Building Code (UBC) and the Canadian Standards Association (CSA). Each lumber was graded by the quality, which is referred to as “No. 1 – Blue,” “No. 2 – Red,” and “No. 3 – Black.”

According to the CSSB-97 revised in 2006 (certified with UBC 15-4 and CSA 0118.1-97), No. 1 grade requires following criteria:

- Clearness on all surfaces

- No sapwood (outer, living layers of the woods engaging in the transportation of water and minerals)

- Not flat grain (woodcut with the growth ring)

- No checks (any split or separation of the wood)

- No defects

- 4 inches of width with 10% of undersize (minimum 3 inches)

- ¼-inch of off-parallel

Furthermore, the length and thickness need to satisfy specific criteria for each size.

No. 1 to 16” XXXXX shingles are at least 15 inches in length with a 5-inch exposure line (the line created by the next row of shingles when properly laid on a roof) and at least 2 inches in thickness of five butts (thick ends of the shingle). No. 1 to 18” Perfection shingles require a minimum 17-inch in length with a 5½-inch exposure line and 2¼-inch thickness of five butts.

Nobuto Arai

Multicultural Research Assistant

August 14th, 2024